Oh my goodness! I can’t believe that its been three months since I checked in with you lovely folks! It seems to me that we were able to achieve more tangible and timely results when the worksite was an hour plus drive away! Looking at the job site directly across the street from where we live presently seems to be both a hindrance to productivity as well as a constant source of anxiety, a reminder that we do not appear to be making visible, tangible strides in the process.

Life happens. Spring rolls around and there are other obligations. The weather breaks and the yard needs tending to, especially after a rather relentless winter. Part-time job gets busy, consultation season gets up and running, the studio is full of client projects and so forth and so on. I tend to forget what we have accomplished so much with our own four hands when things don’t appear to be moving along at a pace which I had envisioned.

Anyway…

When I last posted, the frame was erected and we were making slow but reasonably steady progress on assembling the exterior of the Lustron. Once the majority of the Surf Blue panels were installed, we addressed the roof. We began on the “field side” aka “kitchen side” of the house. The plan was to first install the gutters followed by the leading edge row of roof panels and subsequent two courses of panels by means of a ladder and scaffolding situated within the interior of the Lustron. From there, the remaining eight rows would be placed more easily from the roof.

With three rows in place, disaster struck again. High winds began lifting the roof panels at the weather side of the house. By the end of this latest weather event, we had lost two and a half of the three rows we had just finished installing. Dejected once again, we spent a week banging away on the detached panels in an attempt to salvage their twisted flanges. Cracked off porcelain will be addressed at a later date.

the aftermath of our latest windstorm – ripped off like post-it notes

bent and twisted flange – one of many

Having gone through this experience, we realized we needed to get each side of the roof, all eleven rows, done in its entirety and that we needed to get the ridge cap on asap to hold the entire system together. We hired a couple of guys and did just that.

three more to go then the ridge cap

With both sides of the roof and ridge cap in place, we thought we were home free. NOT! Again with the gale force winds…!!! This time the roof panels started lifting off which necessitated climbing on the roof mid-storm , drilling holes in the leading gable end panels and adding exterior screws to keep the roof from being ripped off.

With both sides of the roof and ridge cap in place, we thought we were home free. NOT! Again with the gale force winds…!!! This time the roof panels started lifting off which necessitated climbing on the roof mid-storm , drilling holes in the leading gable end panels and adding exterior screws to keep the roof from being ripped off.

here we go again…

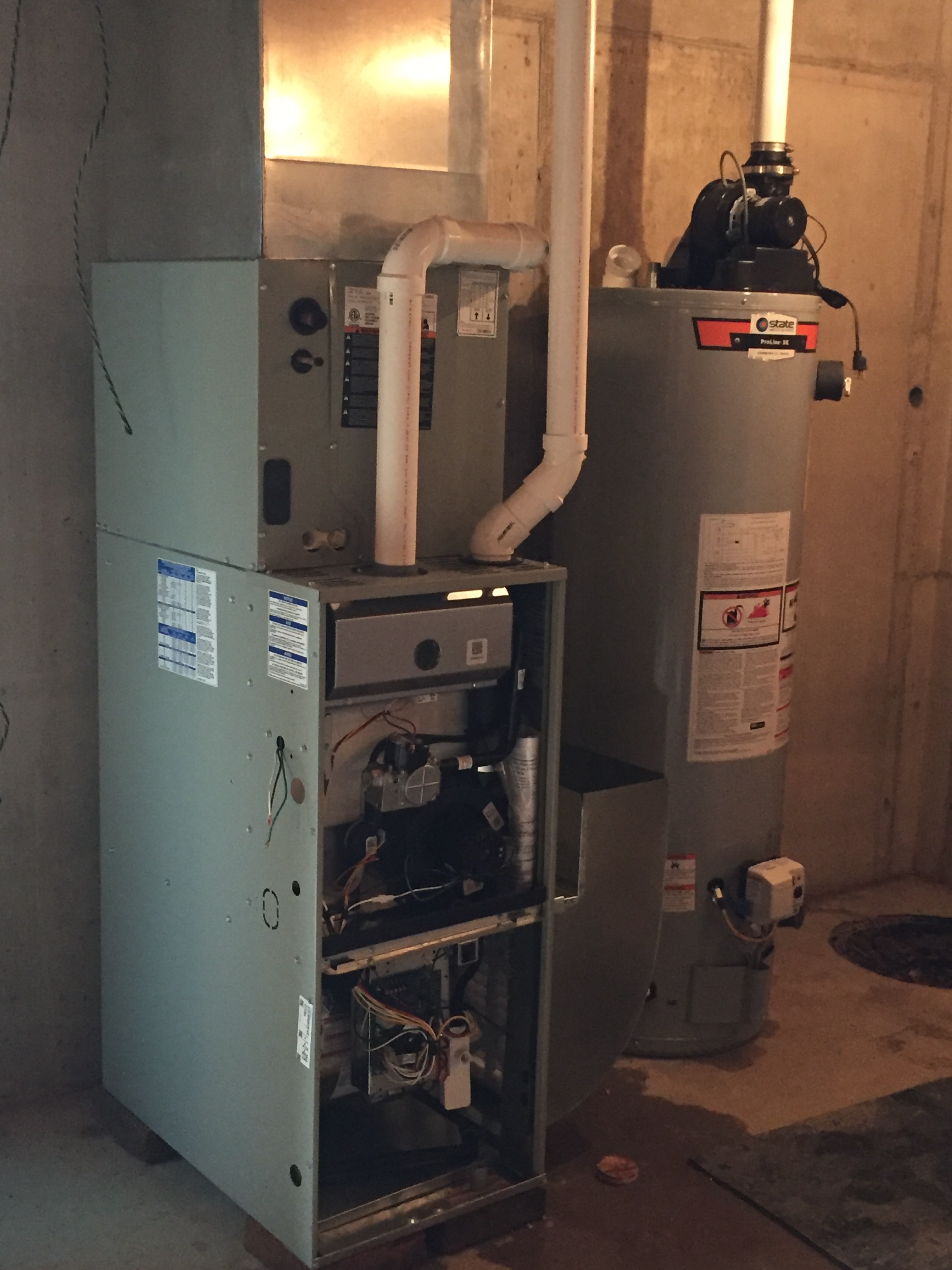

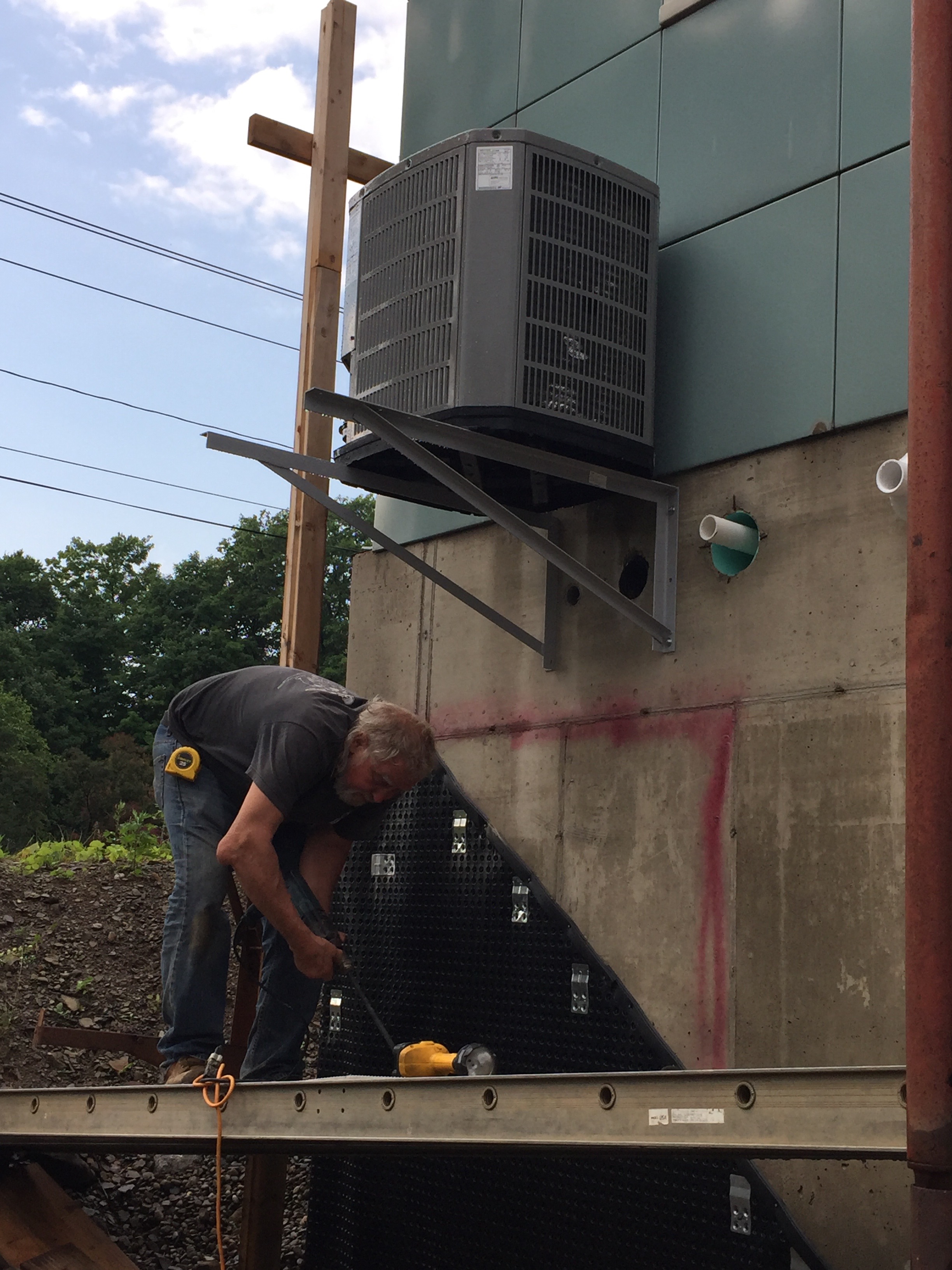

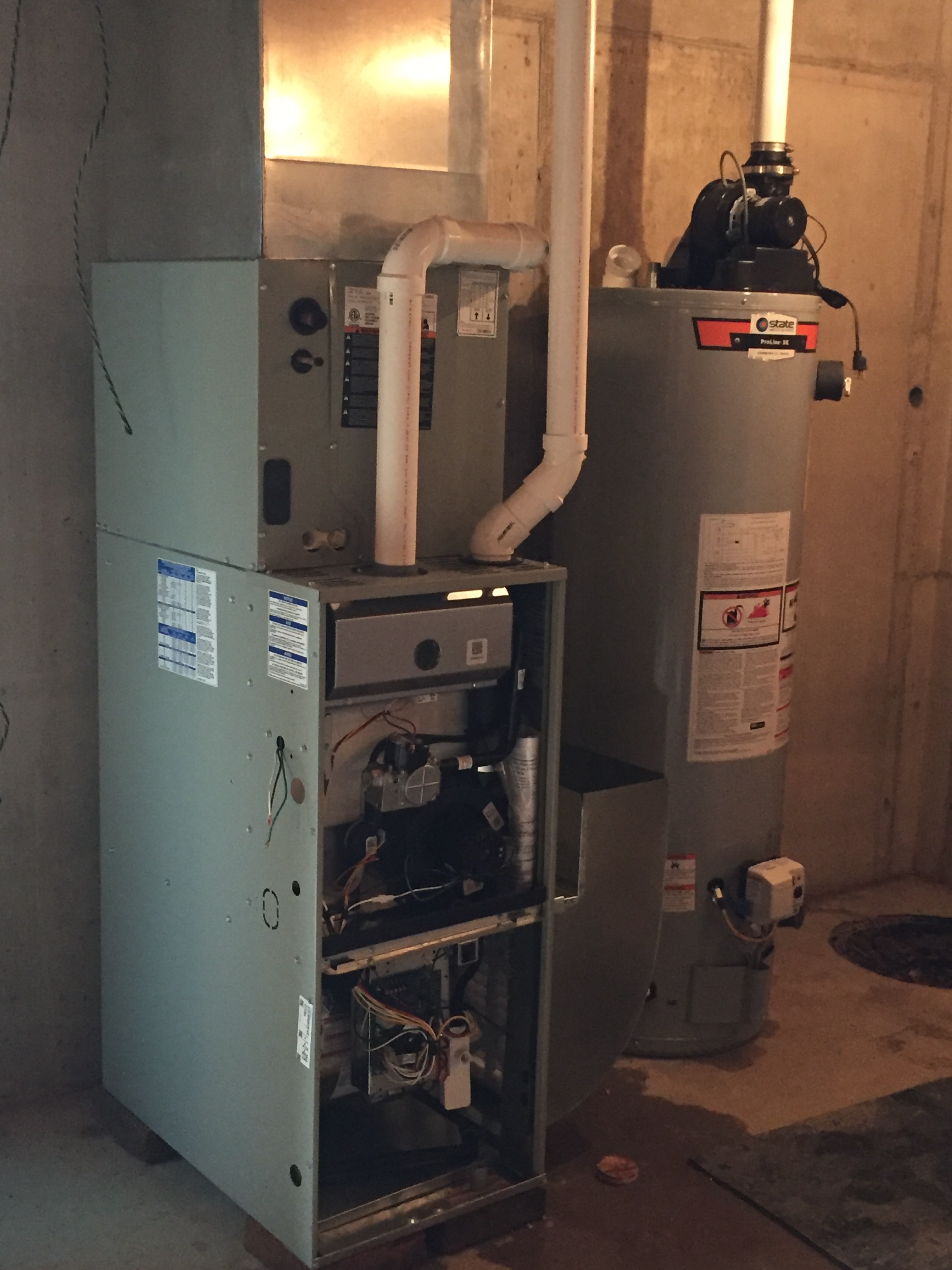

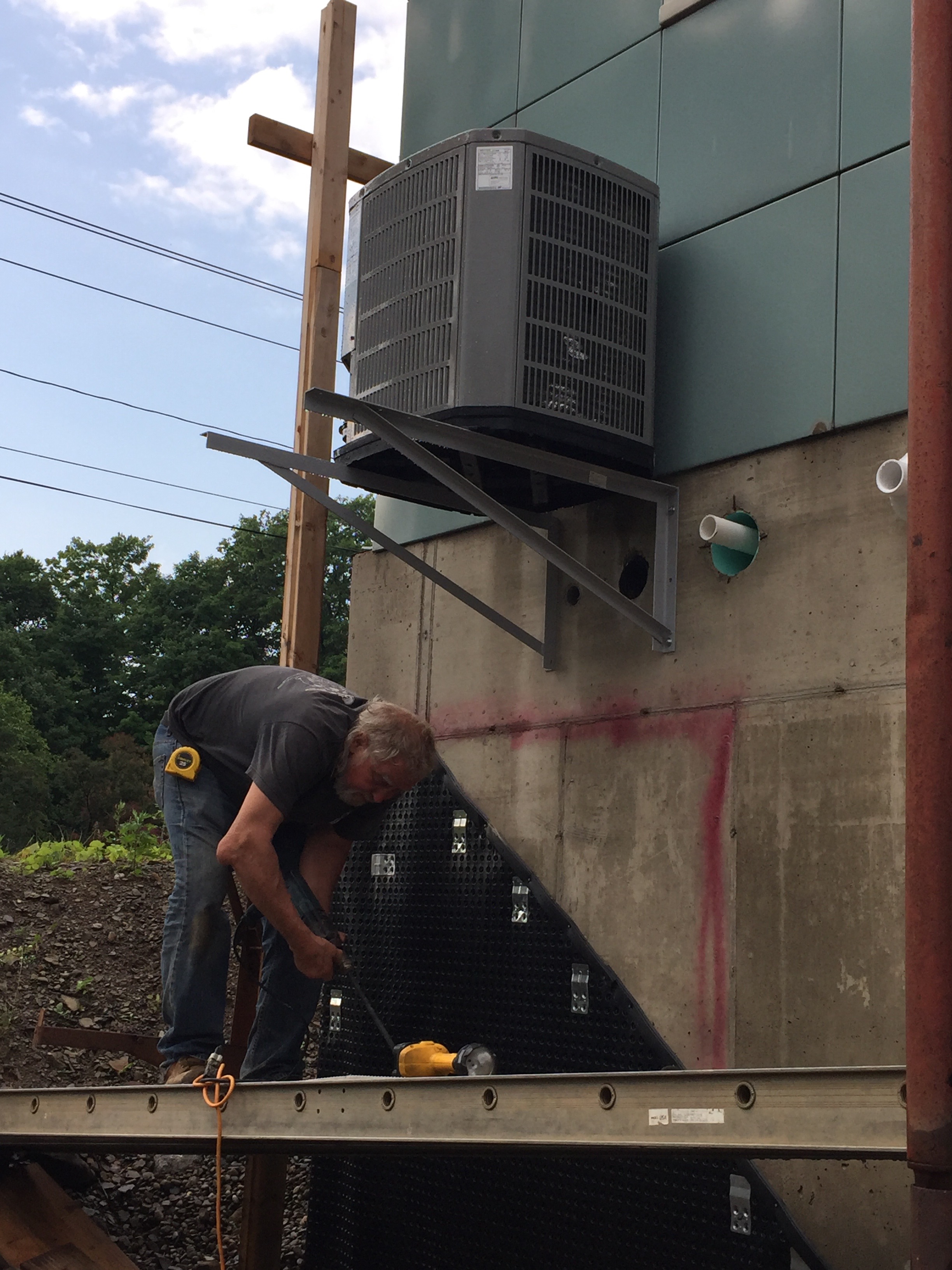

So, three months later, the roof is still in place! I spent a month and a half shooing robins out of the structure, hell bent on setting up house before us. Also tired of paying rent on a trailer, we purchased a tent in which to house the interior panels, cabinets etc. We spent a few days unloading and stacking. From the outside things don’t look very different but we have been working inside as time and finances have allowed. The heating and cooling system was ordered and is in the process of being installed.

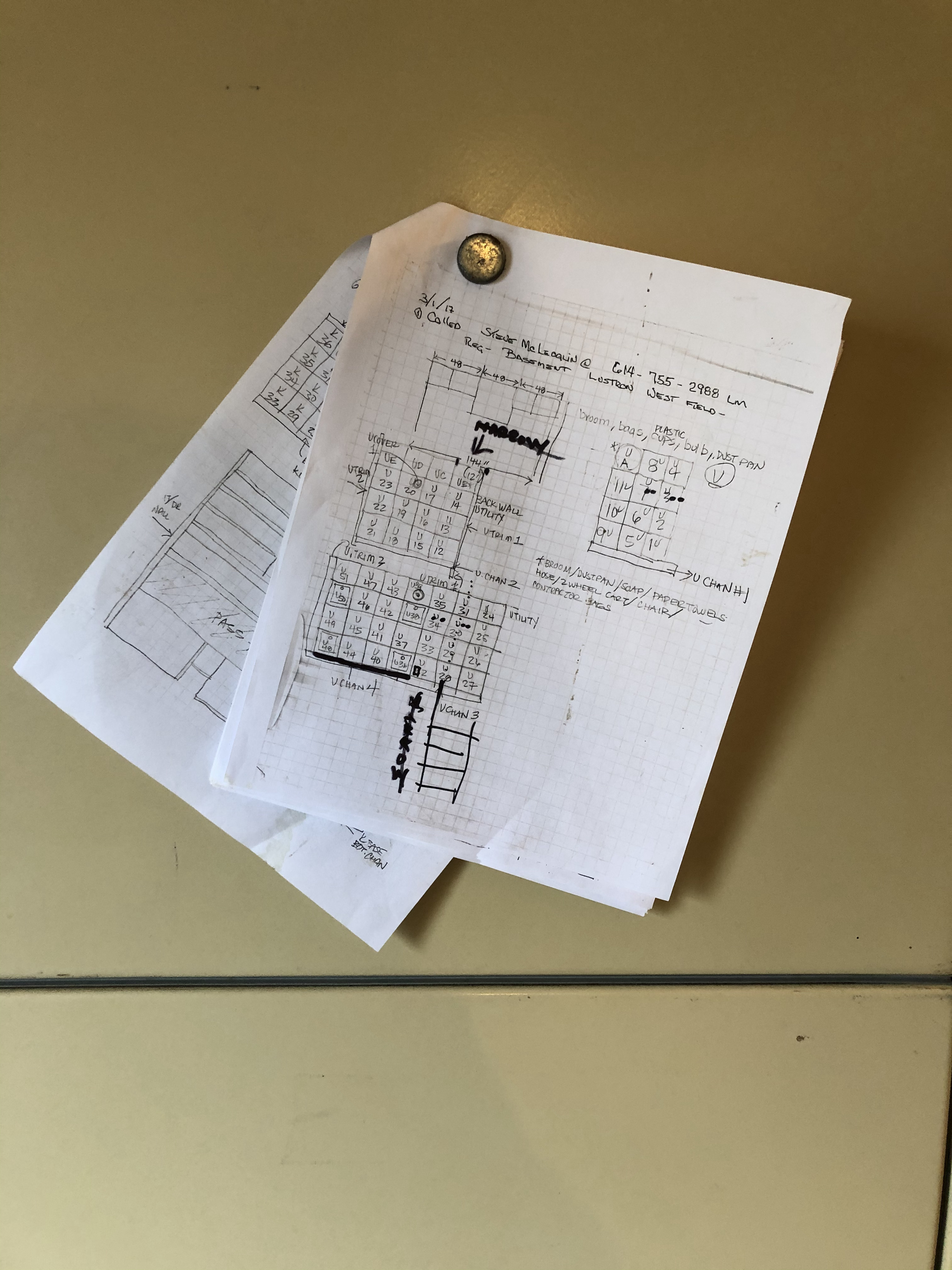

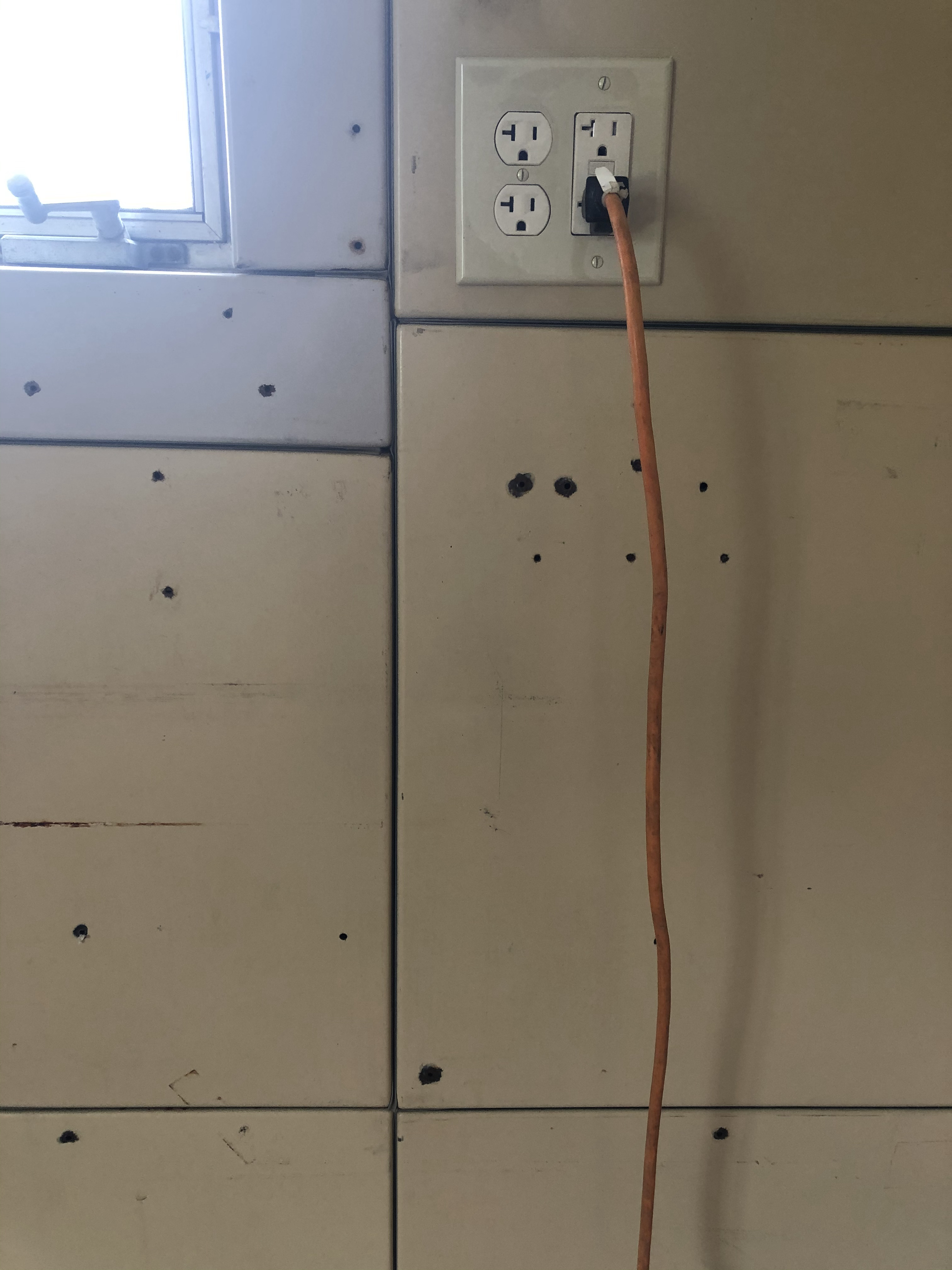

Scheduling other folks has been our latest dilemma. We have been scouting quotes for closed cell blown insulation. The plan is to do a light spray on the underside of the roof and the inside surface of the end gables to hold things together. The interior walls will get three and a half inches blown in once the electric has been replaced. Logistically it will be impossible to spray the top side of the ceiling 4×4’s so we will probably add a layer of foam board insulation cut to size and an additional layer of pink rolled fiberglass as we go along. Our hope is that doing it in this manner and keeping the gable end soffit vents unobstructed will help us to avoid condensation in the “attic” space. The basement will be foam board with metal studded walls covered in either drywall or pine paneling. We are also waiting on the heavy equipment guy’s schedule to clear up so we can dig and install our septic system, trench for utilities and bring in additional gravel fill to bring the yard up to grade. Once that is complete, we can retrieve the Lustron garage and place it on the slab.

Scheduling other folks has been our latest dilemma. We have been scouting quotes for closed cell blown insulation. The plan is to do a light spray on the underside of the roof and the inside surface of the end gables to hold things together. The interior walls will get three and a half inches blown in once the electric has been replaced. Logistically it will be impossible to spray the top side of the ceiling 4×4’s so we will probably add a layer of foam board insulation cut to size and an additional layer of pink rolled fiberglass as we go along. Our hope is that doing it in this manner and keeping the gable end soffit vents unobstructed will help us to avoid condensation in the “attic” space. The basement will be foam board with metal studded walls covered in either drywall or pine paneling. We are also waiting on the heavy equipment guy’s schedule to clear up so we can dig and install our septic system, trench for utilities and bring in additional gravel fill to bring the yard up to grade. Once that is complete, we can retrieve the Lustron garage and place it on the slab.

We have wrapped up the interior painting projects with just a wee bit of touchup to do.

We have wrapped up the interior painting projects with just a wee bit of touchup to do. Last week we installed Armstrong VCT in the bathroom.

Last week we installed Armstrong VCT in the bathroom. Next up is the kitchen and utility room.

Next up is the kitchen and utility room.

Our appliances were delivered a month and a half early but at least I have someplace to keep the beverages cold!

Our appliances were delivered a month and a half early but at least I have someplace to keep the beverages cold! I can hardly wait to get this baby up and running!

I can hardly wait to get this baby up and running! It’s been more than 75 years since the start of World War II – a time in our history when all were asked to make sacrifices for the greater good of our nation.

It’s been more than 75 years since the start of World War II – a time in our history when all were asked to make sacrifices for the greater good of our nation.

With the foaming of the exterior walls complete, things start to get exciting!

With the foaming of the exterior walls complete, things start to get exciting!

Done.

Done.

Between the unrelenting rain storms in the spring we managed to put the cinderblocks in place on the concrete pad onto which the garage would eventually be placed, filling the cells with concrete to accommodate the bolts which would be used afix the wooden sill plate to the block.

Between the unrelenting rain storms in the spring we managed to put the cinderblocks in place on the concrete pad onto which the garage would eventually be placed, filling the cells with concrete to accommodate the bolts which would be used afix the wooden sill plate to the block.

We spent the next couple of days squaring up, pushing and pulling, jacking up and lowering until we got her situated just right.

We spent the next couple of days squaring up, pushing and pulling, jacking up and lowering until we got her situated just right. Now all the bits and pieces have been reunited – a definite load off my mind!

Now all the bits and pieces have been reunited – a definite load off my mind! As 2018 draws to its conclusion I am compelled to evaluate the year’s accomplishments, fraught with setbacks as they were.

As 2018 draws to its conclusion I am compelled to evaluate the year’s accomplishments, fraught with setbacks as they were.

With the septic and utility lines in place, we brought in additional gravel fill, backfilled the trenches and graded the property (it had stopped raining for like 3 days).

With the septic and utility lines in place, we brought in additional gravel fill, backfilled the trenches and graded the property (it had stopped raining for like 3 days).

I absolutely adore vintage bathrooms. I am forever snapping photos of estate sale powder rooms, often throwing caution to the wind, sneaking into off limits rooms just to get a glimpse of linoleum floors, etched shower enclosures, wallpaper and black bullnose tile detailing.

I absolutely adore vintage bathrooms. I am forever snapping photos of estate sale powder rooms, often throwing caution to the wind, sneaking into off limits rooms just to get a glimpse of linoleum floors, etched shower enclosures, wallpaper and black bullnose tile detailing.

I dreamt of one day having a pink and black bathroom of my very own, resplendent with kitschy poodle decor. My plan was to hit up my local ReUse and similar salvage places in hopes of finding vintage pink fixtures for the the Lustron garage. Before I had the opportunity to check, these beauties just about fell into my lap through a friend who’s neighbor was demoing a property.

I dreamt of one day having a pink and black bathroom of my very own, resplendent with kitschy poodle decor. My plan was to hit up my local ReUse and similar salvage places in hopes of finding vintage pink fixtures for the the Lustron garage. Before I had the opportunity to check, these beauties just about fell into my lap through a friend who’s neighbor was demoing a property. Another friend graciously gifted me a set of pink wall inserts for above the sink, the kind that hold a water glass and bar of soap. I’m now on the hunt for the matching recessed wall mounted toilet paper holder.

Another friend graciously gifted me a set of pink wall inserts for above the sink, the kind that hold a water glass and bar of soap. I’m now on the hunt for the matching recessed wall mounted toilet paper holder.

With both sides of the roof and ridge cap in place, we thought we were home free.

With both sides of the roof and ridge cap in place, we thought we were home free.

Scheduling other folks has been our latest dilemma.

Scheduling other folks has been our latest dilemma.

We were on a roll and then March hit. We fared a bit better than our neighbors to the East but a series of four Noreasterns in three weeks blessed us with 20 inches of heavy snow and frigid temperatures. To make matters worse, gusty winds in the 40 plus mph range blew off all of our front end gable panels leaving the flanges bent and corners crumpled. Porcelain does not do well when it hits the ground from a mere inch – you can imagine how it might fare from a height of ten feet!

We were on a roll and then March hit. We fared a bit better than our neighbors to the East but a series of four Noreasterns in three weeks blessed us with 20 inches of heavy snow and frigid temperatures. To make matters worse, gusty winds in the 40 plus mph range blew off all of our front end gable panels leaving the flanges bent and corners crumpled. Porcelain does not do well when it hits the ground from a mere inch – you can imagine how it might fare from a height of ten feet!

The following day the house was down, loaded and transported to the building site by the end of the day. Everything arrived safely including the windows which we left in the wall sections.

The following day the house was down, loaded and transported to the building site by the end of the day. Everything arrived safely including the windows which we left in the wall sections.